As part of their 25th-anniversary celebrations, BMW is introducing 3D printing into their manufacturing process. BMW Head of Production Strategy, Technical Integration and Pilot Plant Dr. Udo Haenle shares that additive manufacturing, or 3D printing, has become a huge part of the car manufacturing process, and BMW is only adjusting to the times.

BMW is Testing A Continuous Liquid Interface Production Technology

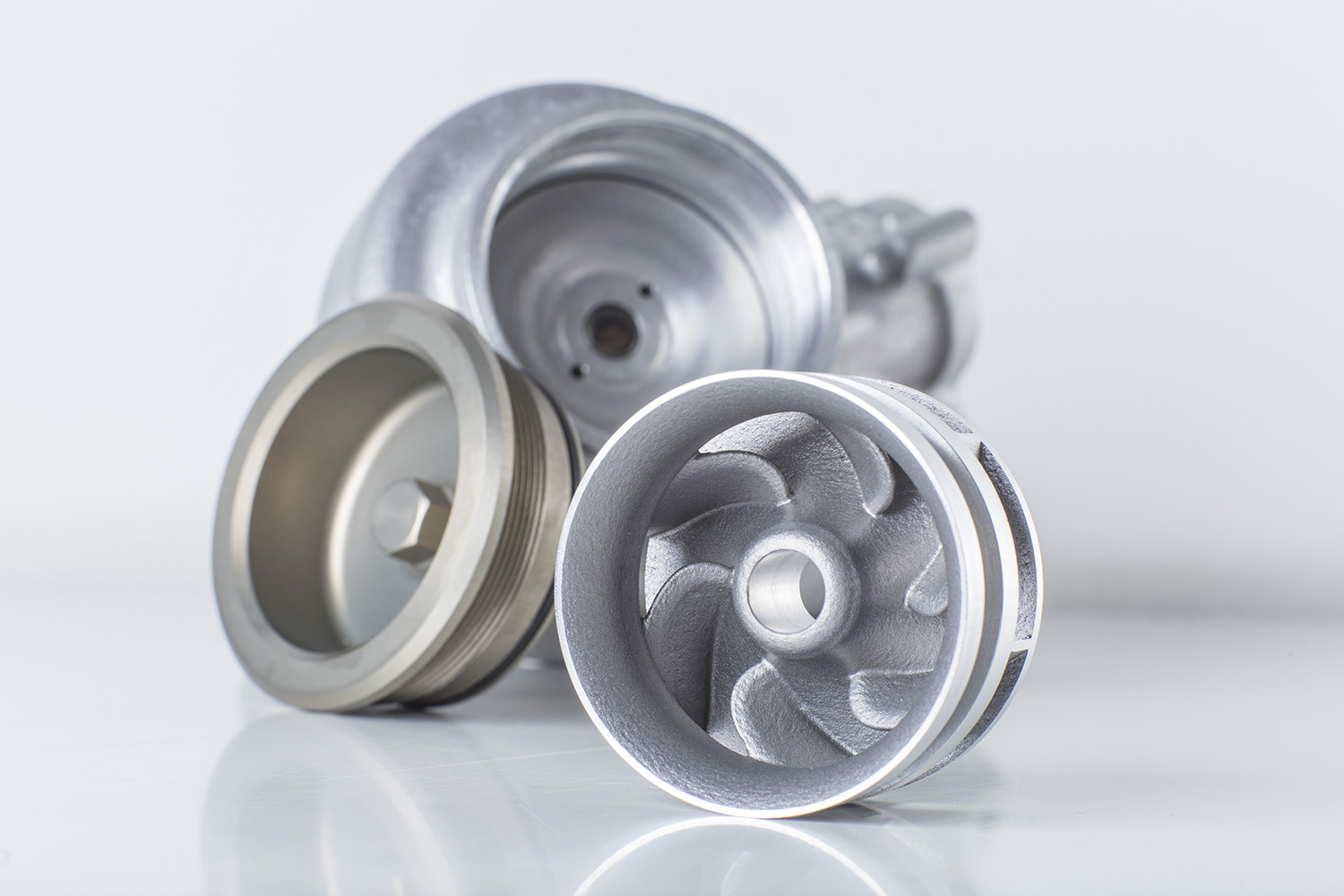

In this day and age, 3D printing is implemented into various specific parts of the car making process, including pre-development, vehicle validation and testing, and for concept car making, as well as toolmaking and operating resources. BMW brought in a 3D printed ergonomic tool in mid 2014 to protect workers’ thumb joints as they work, and they’ve moved on to replace much of the small metal parts in the manufacturing process with 3D printed tools.

3D Printing Has Been A Part of BMW Manufacturing For Years

3D printed BMW parts are not limited to the pre-development and development process. In fact, BMW has been putting 3D-printed water pump wheels into their cars for several years. They’re really only looking to expand, and these efforts will surely come to grow until 3D printing can be a part of all parts of the car making process.