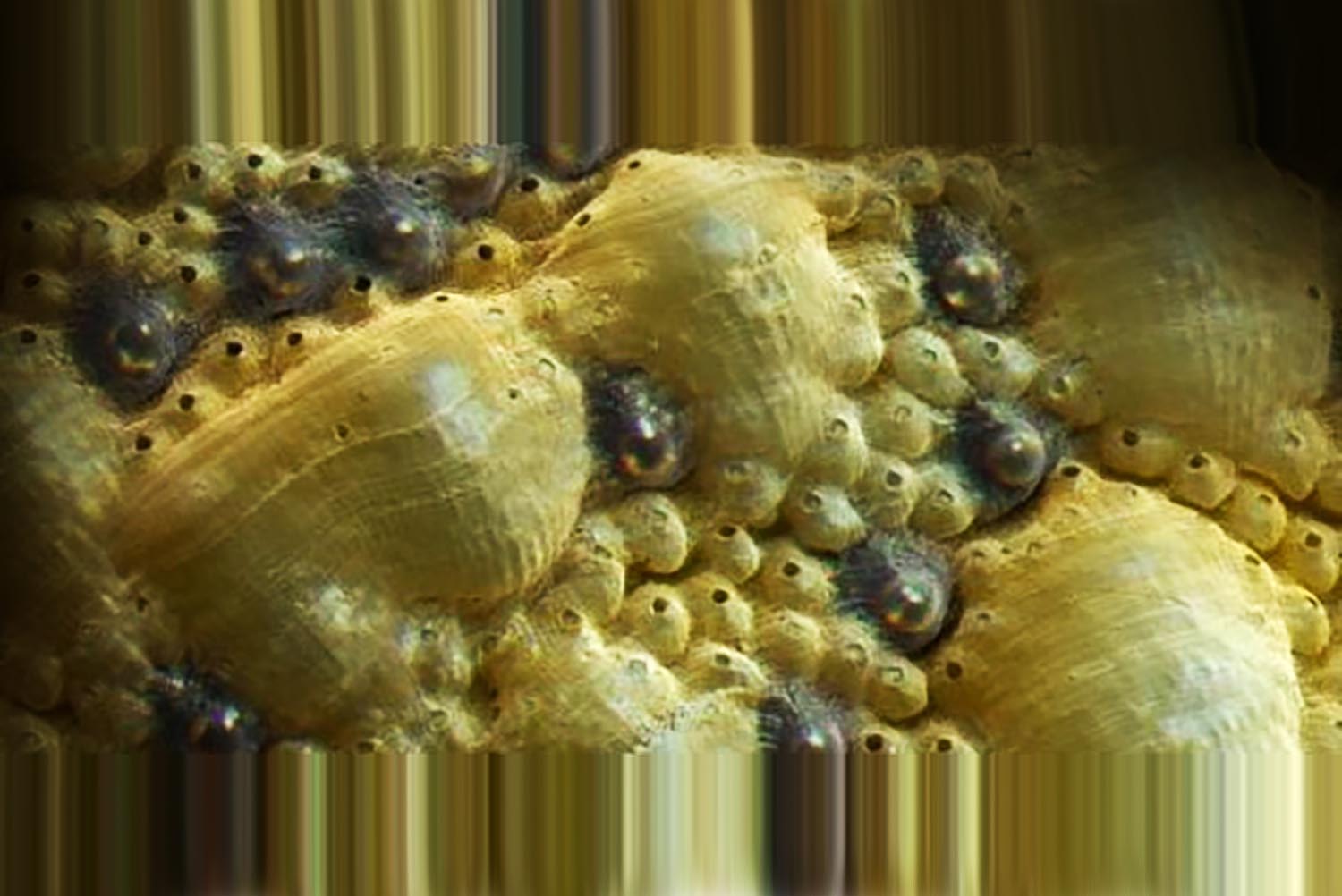

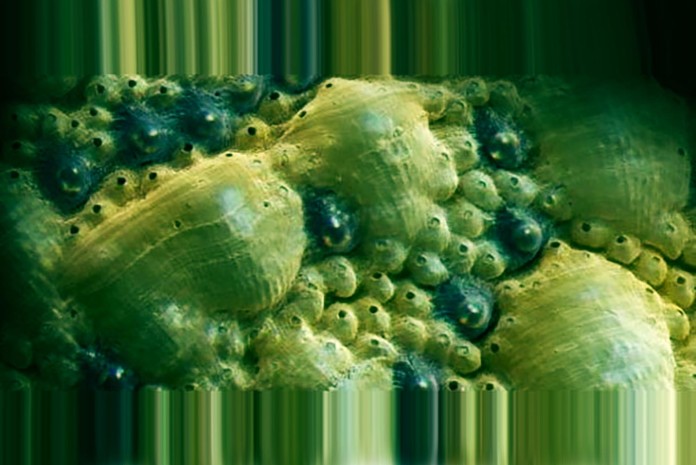

A new study reveals that a one-of-a-kind mollusk species has developed eyes in its shell. With ceramic lenses made from the exact same material as its shell, the Acanthopleura granulate has found a means to sidestep the evolutionary compromise that forces most mollusks to sacrifice sight for security.

Evolution Strikes Again

Acanthopleura granulate is a species of chiton, a class of huge armor-plated marine mollusk. In a new paper in the journal Science, an international team of researchers explained the species’ unique aesthetic system. Unlike nearly every other species, whose eyes are constructed from proteins, this uncommon chiton used aragonite, a mineral its shell is made of, to develop sight. According to the research team, this enable the mollusk to check its atmosphere with their protective armor shell. It’s easy to spot these orbs as eyes, because while the entire shell is opaque, the eyes are crystal clear.

Crystal Clear Image for Predator Watching

A previous research study verified these mollusk’s eyes to be just like human eyes, with lenses that concentrate light on a photoreceptor-covered retina, producing an actual image. To measure the eyes’ concentrating prospective, the team popped a couple of eyes from the shell and also put them under the eye of the microscope. The lenses themselves concentrate a crisp picture. The retinas are tiny but can host many receptors. Each chiton eye generated a tiny pixelated photo.

Chitons shouldn’t be able to see all that well, this mechanism merely allows them to know if a predator is nearby. If so, the mollusk will wedge itself between stones till the threat has actually passed.

The Applications of this New Research Could Be Great

Scientists hope their analysis on this mollusk could lead to material scientific research applications in the army as well as hefty sector areas. Soldiers and employees running under dangerous problems can gain from greatly safeguarded eye wear.