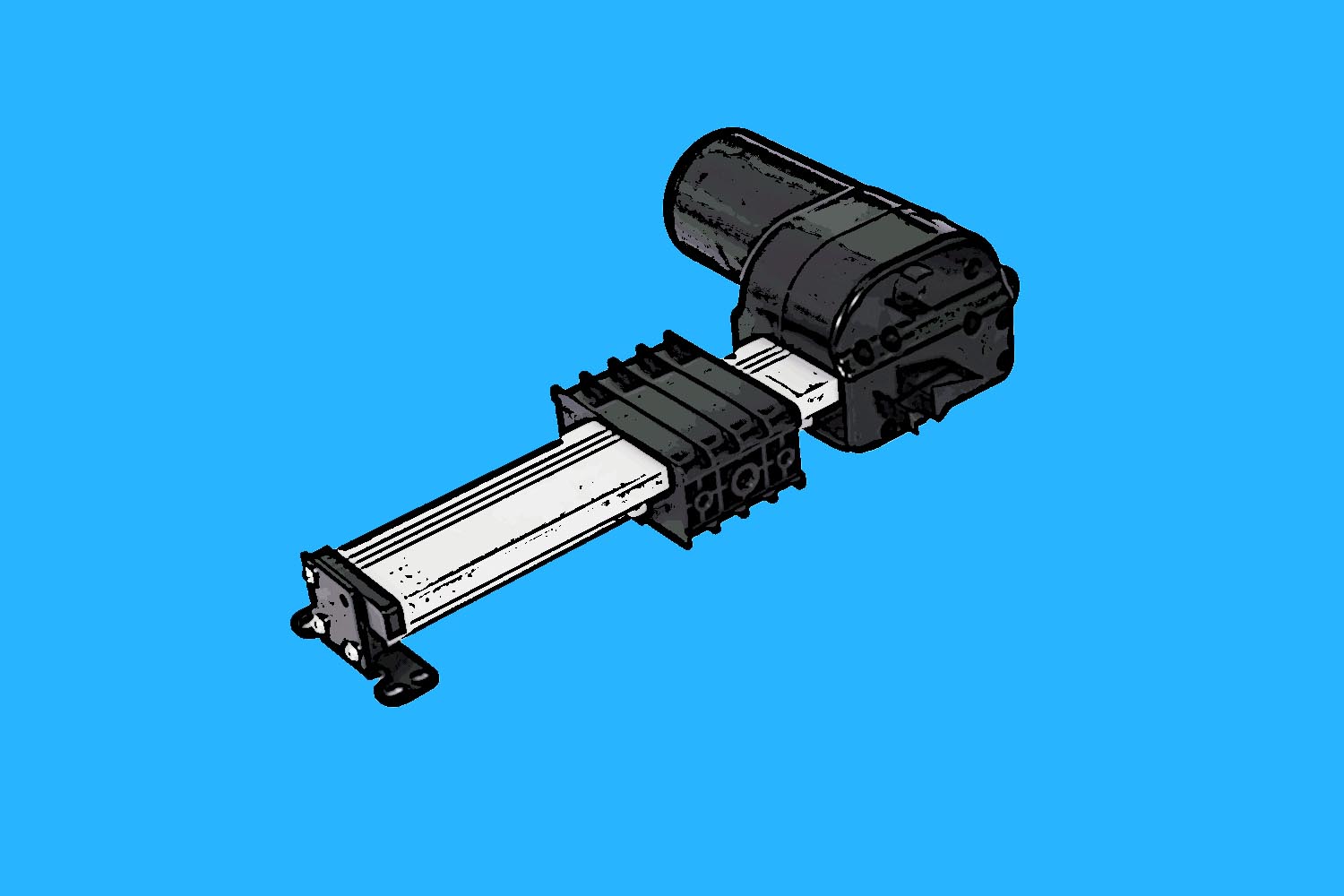

A new trend is hitting the technology world to make all of your devices cleaner, quieter and greener: electric actuators. Actuators are devices that transform energy drawn from air, electricity or liquid to create motion in a straight line. This is the opposite of an electric motor, which moves in circles. An electric actuator specifically converts electrical energy into mechanical torque, and it is one of the cleanest forms of actuator since it does not require oil.

The Electric Actuator Will Make You A Little Greener

Using clean energy and going green is more important now than ever before. Linear actuators are perhaps the most overarching of electric actuators, because it has a very wide range of applications.

The principle of operation of electric actuators is an inclined plane. On it, threads of a lead screw make for a continuous ramp, which makes way for the use rotational force over long or short distances to move a heavy load short distances.

How Do Electric Linear Actuators Work?

There are a few different ways in which actuators can work. Most actuators are composed of a piston, which moves against fluid, air pressure or electricity. It’s made up of a short cylinder fitted to a vessel, where it moves back and forth.

The Uses for an Electric Actuator Are Endless

People can find electric actuators anywhere. Most commonly, they’ll be in industrial automation, machinery or machine tools. They can also be found in computer disk drives, printers, data storage. Not only that, but actuators can be found in the home as well, in garage doors, packaging and laser processing.

Actuators can also be found in motors, valves, pumps, switches, dampers and anywhere linear motion is necessary. They also have appearances in the medical field, for medical imaging and diagnostics. They form part of solar applications, farming, construction, automotive and robotics platforms as well. All in all, everyone can use at least one electric actuator.

There are A Few Drawbacks to Using Electric Actuators

Although there are a lot of perks to using electric actuators, which even have uses for micro-mechanical hardware. But there are a few drawbacks. Electric actuators are mostly manual devices, and cannot be automated. Some actuators aren’t as fast as those that use oil, and they can only cross small distances. They are also quite expensive and require really high voltage to work well. In addition, electric actuators need a secondary force to push their shaft back to position.

Still, it’s a small sacrifice to be made for a greener world. With this many applications, these small devices could change the way a lot of industries use power.